12,80 mm - DRILL BIT MICROGRAIN DIN6537L CNC - ALTIN

- 6537

- L

- Micrograin

- CROMAX

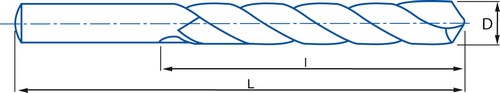

- 12.80

- 14

- 124

- 77

- 2

- 140º

- Flat

- 1

- Steel

- Aluminium-Magnesium

- Copper-Bronze-Brass

- Thermo-Resistant Alloys

- Cast Iron

- Stainless

- Ferritic / Martensitic Stainless (<320 HB / <850 N/mm2)

- Titanium Alloys

- Cast Iron (200-300 HB / 700-1000 N/mm2)

- Austenitic Stainless (<250 HB / <850 N/mm2)

- Materiales resistentes al desgaste (400-500 HB / 1300-1800 N/mm2)

- Cast Iron (<200 HB / <700 N/mm2)

- Treated / Heat-Treatable Alloyed Steel (300-400 HB / 1000-1300 N/mm2)

- Alloyed Steel (<300 HB / <1000 N/mm2)

- 45-55 HRC

- Construction / Carbon Steel (<250 HB / <850 N/mm2)

- Alloys Al-Mg Si < 10% (<180 HB / <600 N/mm2)

- Al-Mg non-alloyed (<100 HB / <350 N/mm2)

- Long Chip Copper-Bronze-Brass (<200 HB / <700 N/mm2)

- Short Chip Copper-Bronze-Brass (<200 HB / <700 N/mm2)

- Alloys Al-Mg Si > 10% (<180 HB / <600 N/mm2)

- 0.090

- 0.240

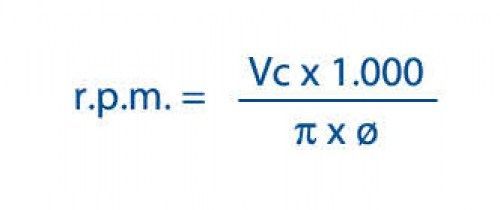

- 90-110

- 0.060

- 0.140

- 40-80

- 0.040

- 0.090

- 30-40

- 0.030

- 0.062

- 15-30

- 0.035

- 0.062

- 35-45

- 0.045

- 0.100

- 40-70

- 0.090

- 0.240

- 40-100

- 0.080

- 0.200

- 40-60

- 0.040

- 0.100

- 30-40

- 0.090

- 0.240

- 50-150

- 50-150

- 0.090

- 0.240

- 80-300

- 0.090

- 0.240

- 80-300

- 60-150

P.1 Construction / Carbon Steel (<250 HB/<850 N/mm2) Feed (mm/rev.) 0,240 P.1 Construction / Carbon Steel (<250 HB/<850 N/mm2) Feed (mm/rev.) 0,090

Cutting Speed (m/min.) 90-110 P.2 Alloyed Steel (<300 HB / <1000 N/mm2) Feed (mm/rev.) 0,140

P.2 Alloyed Steel (<300 HB / <1000 N/mm2) Feed (mm/rev.) 0,060 Cutting Speed (m/min.) 40-80

P.3 Treated/Heat-Treatable Alloyed Steel (300-400HB/1000-1300N/mm2) Feed (mm/rev.)0,090 P.3 Treated/Heat-Treatable Alloyed Steel (300-400HB/1000-1300N/mm2) Feed (mm/rev.) 0,040

Cutting Speed (m/min.) 30-40 P.4 Wear-resistant materials (400-500 HB / 1300-1800 N/mm2) Feed (mm/rev. 0,062

P.4 Wear-resistant materials (400-500 HB / 1300-1800 N/mm2) 0,030 Cutting Speed (m/min.) 15-30

M Austenitic Stainless (<250 HB / <850 N/mm2) Feed (mm/rev.) 0,062 M Austenitic Stainless (<250 HB / <850 N/mm2) Feed (mm/rev.) 0,035

Cutting Speed (m/min.) 35-45 P.5 Ferritic/Martensitic Stainless (320HB/<850 N/mm2) Feed (mm/rev.) 0,100

P.5 Ferritic/Martensitic Stainless (320HB/<850 N/mm2) Feed (mm/rev.) 0,045 Cutting Speed (m/min.) 40-70

K.1 Cast Iron (<200 HB / <700 N/mm2) Feed (mm/rev.) 0,240 K.1 Cast Iron (<200 HB / <700 N/mm2) Feed (mm/rev.) 0,090

Cutting Speed (m/min.) 40-100 K.2 Cast Iron (200-300 HB / 700-1000 N/mm2) Feed (mm/rev.) 0,200

K.2 Cast Iron (200-300 HB / 700-1000 N/mm2) Feed (mm/rev.) 0,080 Cutting Speed (m/min.) 40-60

S Heat-Resistant Alloys Feed (mm/0,100 S Heat-Resistant Alloys Feed (mm/rev.) 0,040

Cutting Speed (m/min.) 30-40 N.1 Short Chip Copper-Bronze-Brass (<200 HB / <700 N/mm2) Feed (mm/rev.) 0,240

N.1 Short Chip Copper-Bronze-Brass (<200 HB / <700 N/mm2) Feed (mm/rev.) 0,090 Cutting Speed (m/min.) 50-150

N.2 Long Chip Copper-Bronze-Brass (<200 HB / <700 N/mm2) Feed (mm/rev.) 0,240 N.2 Long Chip Copper-Bronze-Brass (<200 HB / <700 N/mm2) Feed (mm/rev.) 0,090

Cutting Speed (m/min.) 50-150 N.3 Al-Mg non-alloyed (<100 HB / <350 N/mm2) Feed (mm/rev.) 0,240

N.3 Al-Mg non-alloyed (<100 HB / <350 N/mm2) Feed (mm/rev.) 0,090 Cutting Speed (m/min.) 80-300

N.4 Al-Mg Si < 10% Alloy (<180 HB / <600 N/mm2) Feed (mm/rev.) 0,240 N.4 Al-Mg Si < 10% Alloy (<180 HB / <600 N/mm2) Feed (mm/rev.) 0,090

Cutting Speed (m/min.) 80-300 N.5 Al-Mg Si > 10% Alloy (<180 HB / <600 N/mm2) Feed (mm/rev.) 0,240

N.5 Al-Mg Si > 10% Alloy (<180 HB / <600 N/mm2) Feed (mm/rev.) 0,090 Cutting Speed (m/min.) 60-150